NOW, HOW DID THIS HAPPEN…?

This birth of this new Heyman 34 Sport has been a complete joy.

Often, designing a new boat may be like setting off on a wobbly journey. The ideas may be dim, and one or two ideas may be in direct conflict.

In the case of this new high-performance yacht, we had nothing of this.

To start with, our client had a clear idea what he wanted in his new boat:

+ It must be able to sail a lot faster than displacement speed

+ Easy to handle, without any adaptation to measurement rules

+ A functional and lightweight interior with room for four persons

But also from our side, we were in a position to tell with some accuracy what would work.

In the end, I believe we were extremely lucky during the design of our new 34 Sport:

– Lucky to start off not only with clear ideas about concepts, hull shape, appendages, rig, handling and layout.

– But lucky also to note how all aspects fell in place, each detail contributing to a stunning overall result.

LONG PROCESS, FAST BOAT

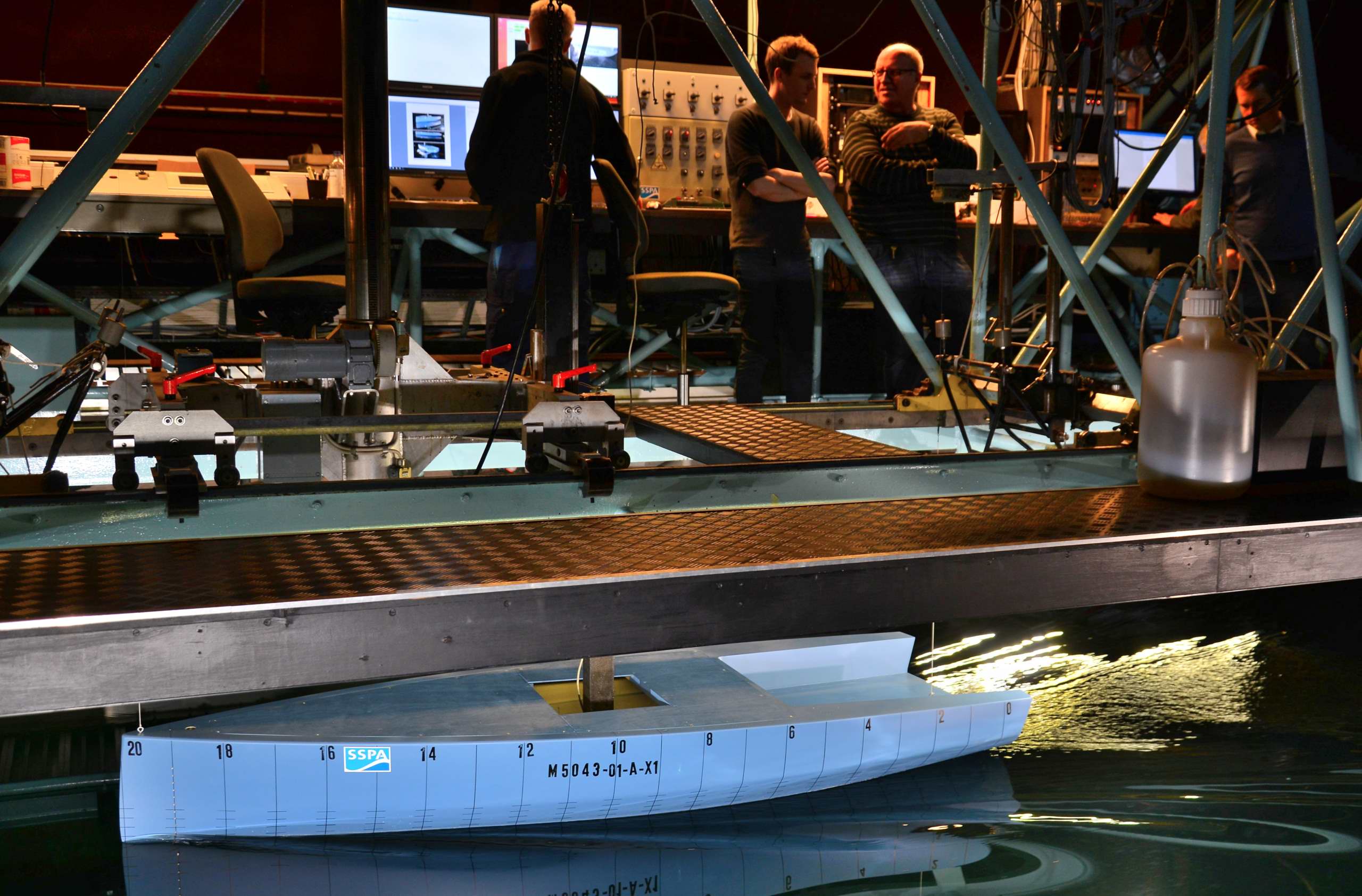

The design of the new 34 Sport was a team effort between a number of key players:

- Studies of hull shapes at Chalmers University of Technology and

also tank testing at SSPA, both under Prof. Lars Larsson - Composite engineers at Gurit (GB) for part of structural design

- The builders of the 34 Sport hull # 1, under Johan Berggren

- Marstrom Composite, for the carbon fibre keel structure

- Selden for optimizing and building the carbon fibre rig

- For the carbon fibre production boat, Vaxholm Komposit

- Strategic decisions and specifications, by the owner Mr Torbjörn Hurtig

- 3D-modelling Christian Wallgren

- Last but – honestly – perhaps not least, our own design team

In her conception , we set out to pay attention to every single aspect of the design and push the boundaries of performance and function. Whether we got any further than the ordinary, others will have to judge…

THINGS WE WANTED TO AVOID

There was one red line – we absolutely did not want to go outside tried-and-tested territory. She had to be a normal boat, as simple as possible given the requirements, totally robust and not overly complicated to build.

The best way to avoid complication or unforeseen clashes in a new design is to discard most of the ideas that may pop up, and use only the viable ones. We were much helped by the fact that the client did not once deviate from his initial requirements.

One thing we wanted to avoid was a T-keel. This is the lead bulb being fitted to the Heyman 34 carbon fin

Also, avoiding twin rudders would be a huge advantage. It turns out that she handles perfectly with one.

PERFECTING A HULL

Sailing performance is dependent on a number of factors, all affecting each other in a complex way: A low building weight and a long waterline obviously, a big sail area and a good righting moment to carry that sail. These are the basics.

We started writing a piece on how to create a fast sailboat, here (and until now only got to the first 2 out of the 7 pillars but I assume the subtitles say a lot regarding the following 5)

Most important though, as a result of the virtual CFD study of 3 different sailboat hulls in waves and the subsequent tank testing in waves at SSPA we were able to confirm our initial assumptions which hull shape would be the fastest:

And it all works.

The prototype, also called Celeste 34, has been thoroughly tested during 2 seasons.

Ease the sheets just a little and bear away 10-15 degrees from close hauled, and she gladly runs beyond hull speed, past 9 – 10 – 11 or 12 knots.

Om a deep reach, she has clocked between 16 and 17 knots continuous speed, with a good behaviour and easy handling. Note that this is in a calm sea state, without any surfing.

(Note also that speed when reaching depends mostly on wind versus sail area, which means she has potential for more depending on the conditions)

A film clip from one such occasion – you can almost touch the excitement:

Another sail clip from sail racing website ‘BLUR’, by editor Peter Gustafsson, with sailmaker Henrik Ottosson of North Sails:

ON DECK

Focus is on ergonomics and comfort. The cockpit is huge by any standard

(click image and it gets even bigger…)

Stanchion bases are a custom design, with a solid deck plate and a unique bayonet fitting for the stanchions

TAMING ALL THAT POWER

Sail handling makes use of unique solutions in combination with off-the-shelf gadgets:

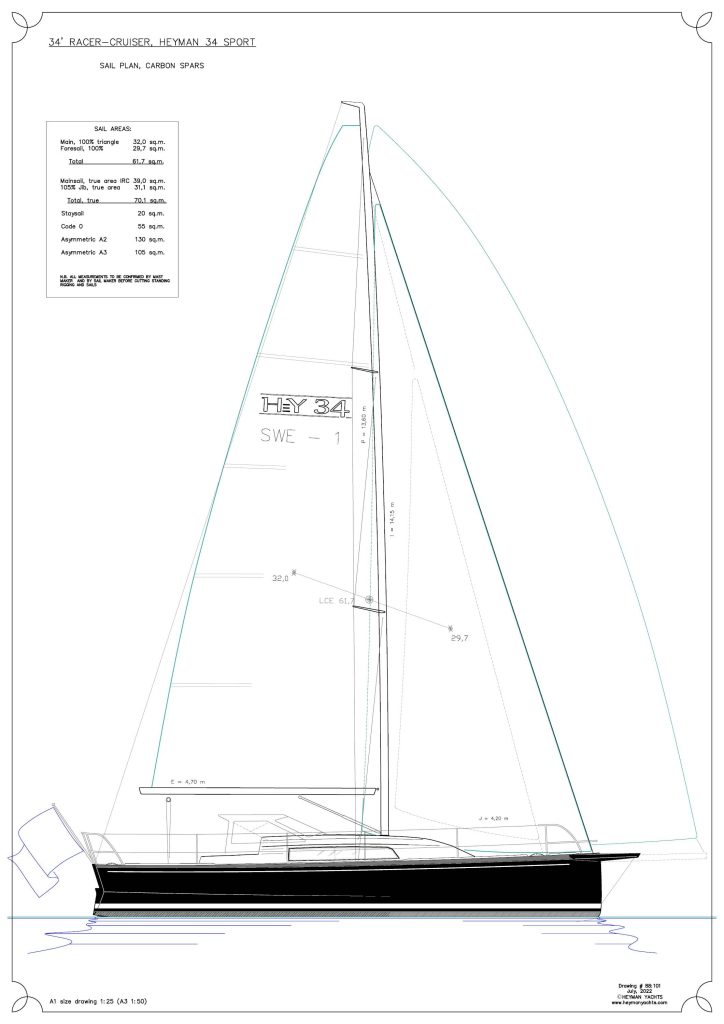

* A fixed bowsprit 80 cm long; strong and stable for a Code O

* A 2,4 m long extendable carbon fiber bowsprit, supported by the fixed bowsprit for the gennaker

* The line to pull out the bowsprit and is lead aft below deck to rope clutches and winches on the coachroof

* Both the gennaker tackline and Code O tackline are also lead aft in the same way. The foredeck is clean

* A floating jib sheeting system for a sheeting angles down to 5-6 degrees

* Winch feeders and turning blocks offer maximum flexibility as to how and from where sheets /trim lines are handled

* Jib with softhanks and a reef

* Mainsheet purchase 5:1/10:1 led to a swivel cam base behind the long traveller track

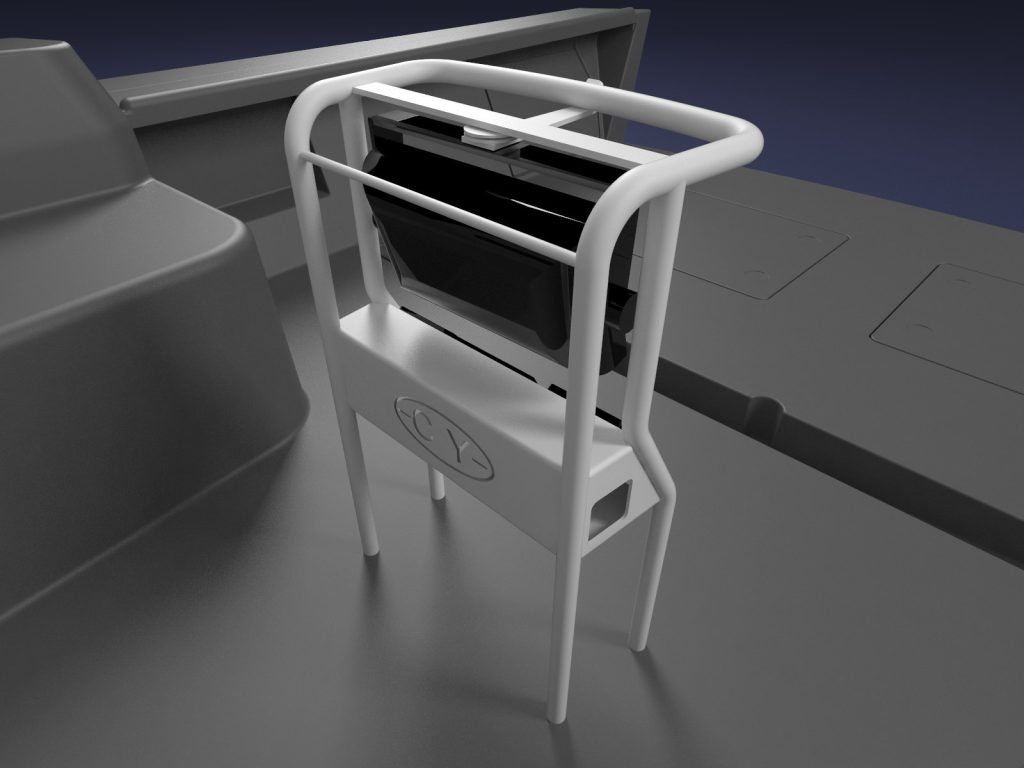

* A pedestal in the cockpit for central placement of the chartplotter, compass and autopilot control, as well as engine control and instrument

* The pedestal also serves as a handhold in the large and spacious cockpit, and can be used to hold a cockpit table

* An autopilot mounted directly on the rudder stock below deck

* Instruments on the mast visible to everyone on board

* Access to sheets and room for instruments also for helmsman, for short-handed sailing

PERFORMANCE NUMBERS

Comparing performance ratios (D/L and SA/D ratios) to four other well-known performance boats may give a hint to the speed potential of the Heyman 34 Sport

(note that this is a selection of some of the best and most up-to-date competition):

LOA Disp S.A. D/L ratio SA/D ratio

Brand A 9,94 m 3,8 tons 63,7 m² 162 26,2

Brand B 9,99 m 3,5 tons 61,9 m² 141 26,9

Heyman 34 10,46 m 3,4 tons 73,0 m² 99 32,3

Brand C 11,00 m 4,8 tons 75,0 m² 112 26,4

Brand D 11,10 m 4,2 tons 61,6 m² 120 23,6

INTERIOR

The prototype has a slightly different layout than the carbon fibre series production boat, with its heads forward and twin aft cabins. The main cabin is similar on both versions, though. All panels are cored construction, with multidirectional glass / carbon fibre, painted white:

UNDER SAIL

Sailing images © Dan Ljungsvik, for Selden Mast

BUILD:

The production version will be built of carbon fibre throughout, both hull and deck. It is expected to be lighter than the prototype, possibly with some more weight to the keel bulb.

The prototype is a stiff and light construction, using multidirectional and unidirectional glass over a Divinycell core. The keel fin is built around a solid carbon fibre T-beam made by Marstrom, with the deep keel ending in a 1000 kg lead bulb.

Carbon fibre rig by Selden. Solid aluminium rudder stock and bearings by Jefa.

Interior / structure is a bright, lightweight monocoque construction with cored floorboards and berth bottoms. In order to reduce weight some interior parts can be lifted out, like the canvas hanging lockers / wardrobes, and the fridge.

DRAWINGS

MORE ON ‘BLUR’

Regarding sail plan and other central aspects, Peter Gustafsson, editor of the BLUR, has posted a few articles. These are more detailed and technical than almost any other published material, no surprise perhaps given Peter Gustafsson’s own racing credentials:

A link to an article about the sail plan.

And an overview of written articles on the 34 Sport, most of them in English (the workname for the boat was then Celeste 34, but same boat)

DIMENSIONS:

LOA 10,45 m

LWL 9,92 m

BEAM 3,49 m

Draft 2,23 m

Displacement 3,4 ton

S.A. 73 sq.m.

I 14,15 m

J 4,20 m

P 13,60 m

E 4,70 m

Motor, electric: 6 kW, Oceanvolt SD6

Batteries: LiFePo4 11,6 kWh and a 90 A 12 V house battery

Price on application.

Contact: Torbjörn Hurtig / Heyman Yachts AB, torbjorn.hurtig@artilux.se

(c) Heyman Yachts 2022